DESIGN, INSTALLATION & TECHNICAL PRODUCT INFORMATIONVisit Lysaght Professionals

12 / November / 2015

Sydney, New South Wales

BUILDER

Macquarie Goodman

FABRICATOR

B & G Welding

PROJECT SIZE

A$125 million

Products

Sydney based company B & G Welding is leading the way in structural steel innovation at one of Sydney's newest business parks in Sydney's inner west.

Located in the geographical heart of Sydney, Lidcombe Business Park offers brand new office and warehouse space, combining quality design, low maintenance finishes, and extensive landscaping. It's being developed by leading property developer Macquarie Goodman. The Macquarie Goodman Industrial Trust is Australia's largest industrial Trust, specialising in warehouse/distribution centres, industrial estates, business parks and office parks.

On completion, the A$125 million Park will include 60,000 square metres of business space, as well as a café and ample parking. Its competitive rents and flexible tenancy areas have already attracted high-profile tenants such as the Commonwealth Bank and Fisher and Paykel.

After an extensive tendering process, B & G Welding was awarded a A$1.4 million contract for the fabrication, supply, and installation of 280 tonnes of structural steelwork for the project by Sydney construction firm, Buildcorp.

"The work is going really well at the moment," says Sonny Bennett, a Director of B & G. "Everything is right on schedule." B & G Welding was established in 1967 by Barry Bennett, father of Sonny and Craig, who both now run the business. With 20 direct employees and another 25 dedicated sub-contractors, B & G Welding offers structural steel solutions for commercial and industrial applications and specialises in portal frame design and construction.

Apart from Lidcombe Business Park, B & G has been involved in a number of major projects around Sydney, including the horse and cattle pavilions at the Sydney Showground in Homebush, Fauldings Pharmaceuticals storage facility at North Ryde, and the Sands Hospital Community Centre in Wahroonga. Other projects include extensions at Nepean Hospital, Penrith, Thornleigh Indoor Sports Centre and the Blacktown Bus Rail Interchange. B & G is also currently working on the new

Lidcombe Business Park comprises seven separate buildings, from Building A, situated on the corner of Parramatta Rd and Birnie Avenue, to Building G, located at the southernmost end of Birnie Avenue. B & G Welding has provided the structural steel for Buildings E and F, which are the only two buildings on site to incorporate the revolutionary new LYSAGHT SupaZed® purlins in their design.

"We made a few design changes on the Lidcombe project," says Sonny. "The engineer initially proposed using traditional Z200 purlins on Buildings E and F, which had been used in all the other buildings on site. We felt that we could make a significant cost saving by using the LYSAGHT SupaZed® purlins recently developed by BlueScope Lysaght. And we passed that saving on to the client, which they were very happy with."

Buildings E and F each cover about 10,000 square metres, and contain about 140 tonnes of structural steel each. BlueScope Lysaght supplied approximately 10,000 linear metres of LYSAGHT SupaZed® purlins and girts for each building.

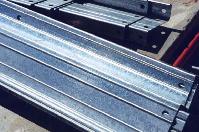

The LYSAGHT SupaZed® purlins are the first significant development in the field for decades. The longitudinal web stiffeners considerably improve the performance of the purlin, allowing it to span greater distances with ease. Strong and versatile, the innovative LYSAGHT SupaZed® design also allows increased spacing and fewer rows of bridging, making it the most cost-effective and efficient purlin around.

Sonny explains, "With the LYSAGHT SupaZed® purlins we can span greater distances with a smaller section. The web stiffeners on the purlin give it greater strength, so we can also increase the spacing of the purlin set out. The result is that we use less material, which is more economical and makes installation faster as well."

According to Sonny, use of the new purlin design has resulted in real cost savings on the project, "I'd say there would be about a 12% saving from using the LYSAGHT SupaZed® rather than traditional purlins. It might not sound like a lot, but on a project of this size, it all adds up."

On a large-scale project such as this, it's imperative that all works are completed on time and within budget. Which is why B & G's relationship with BlueScope Lysaght is so important. "BlueScope Lysaght has been great to deal with as a supplier," says Sonny Bennett. "They've been very professional, and they were really helpful in assisting the design procedure for the buildings - the product support was very good. We've had absolutely no trouble with lead times, and of course, the quality of the product is excellent."

LYSAGHT SupaZed® 200 purlins have now been available in New South Wales for two years, and have enjoyed an extremely positive response in the marketplace. The success of the LYSAGHT SupaZed® purlins has led BlueScope Lysaght to invest in a new state-of-the-art roll former located at its Chullora factory in New South Wales. The new machine will enable BlueScope Lysaght to update its current purlin portfolio to include the SUPA series, which will encompass LYSAGHT SupaZed® and LYSAGHT SupaCee® 150, 200, 250, 300 and 350 purlins.

Sydney, New South Wales

BUILDER

Macquarie Goodman

FABRICATOR

B & G Welding

PROJECT SIZE

A$125 million

Products